A Professional Guide to Selecting the Right Rock Drill Bit

Selecting the optimal button bit is critical for any rock drilling operation. The right choice ensures a high penetration rate, long service life, and maximum productivity. However, with various bit face designs and carbide button shapes available, making the correct decision can be challenging.

This guide outlines the key factors to consider when choosing the best drill bit for your specific needs.

1. Bit Material: The Foundation of Performance

The material of the drill bit is the single most important factor determining its durability and effectiveness. High-quality tungsten carbide is the industry standard for its exceptional wear resistance, toughness, and ability to withstand high-impact forces.

- Key Advantages: Bits made from superior tungsten carbide deliver faster drilling speeds, extended service life, and consistent, reliable performance across various rock conditions.

2. Drill Bit Design: Matching the Bit to the Rock

The design of the drill bit, including its face profile and the shape of the carbide buttons, must be matched to the geology of the drilling site.

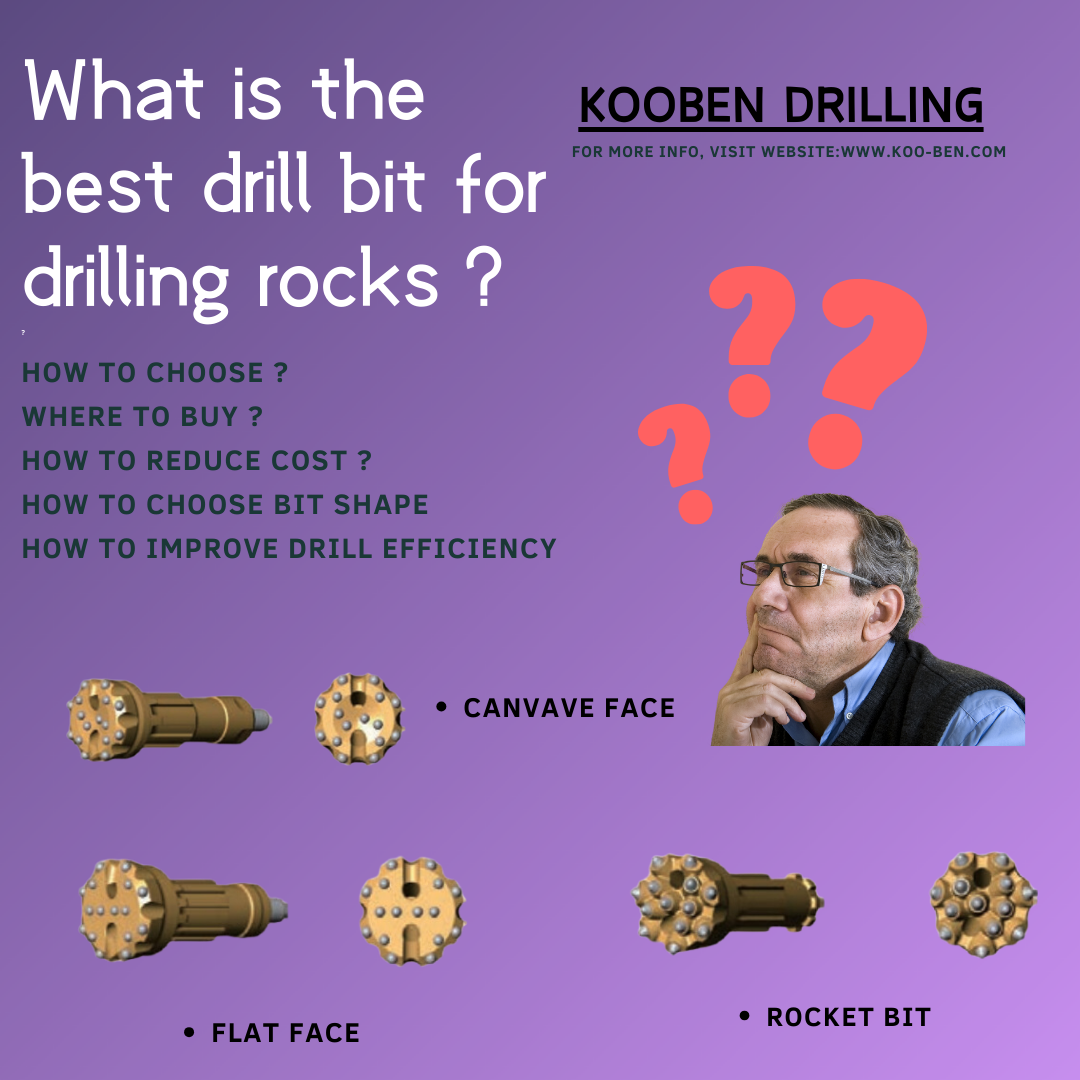

A) Face Design

The face of the bit is its primary point of contact with the rock. Common designs include:

- Flat Face: Ideal for medium-to-hard and abrasive rock formations. It produces straight holes but may have a lower penetration rate.

- Drop-Center (Concave) Face: Excellent for ensuring straight holes in soft-to-medium, fractured, or fissured rock.

- Convex Face: Designed for high penetration rates in soft-to-medium hard rock, though hole straightness may be slightly reduced.

B) Carbide Button Shape

The shape of the tungsten carbide buttons determines how the bit breaks the rock.

- Domed/Spherical Buttons: A universal, all-purpose button shape. It is very strong and resistant to breakage, making it ideal for the toughest and most abrasive hard rock formations.

- Ballistic Buttons: These pointed buttons are designed for maximum penetration. They are best suited for softer and medium-hard rock where speed is the primary goal.

- Semi-Ballistic Buttons: A combination of the two, offering good penetration and solid durability. They are a versatile choice for medium-to-hard rock.

- Conical/Sharp Buttons: Best for high-speed drilling in softer rock formations where high penetration rates are desired and carbide wear is less of a concern.

3. Technical Specifications: Ensuring a Perfect Fit

Finally, you must confirm the technical specifications to ensure the bit is compatible with your equipment.

- Hole Diameter: The required size of the drilled hole.

- Thread Type: The connection interface that screws onto the drill rod (e.g., R32, T38, T45).

- Skirt Design: The body of the bit, which affects how cuttings are flushed from the hole.

Conclusion

Choosing the best drill bit is a crucial decision that directly impacts operational efficiency and cost. By carefully considering the bit’s material, its design, and its technical specifications, you can select a tool perfectly suited to your application. This strategic choice will help you maximize productivity, reduce downtime, and achieve lower overall drilling costs.

Post time: Mar-13-2024